- HOME

- PRODUCTS

- ABOUT US

- Panorama

- Download

- NEWS

- CONTACT

(1).jpg)

(1).jpg)

.jpg)

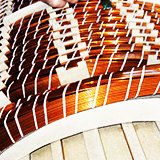

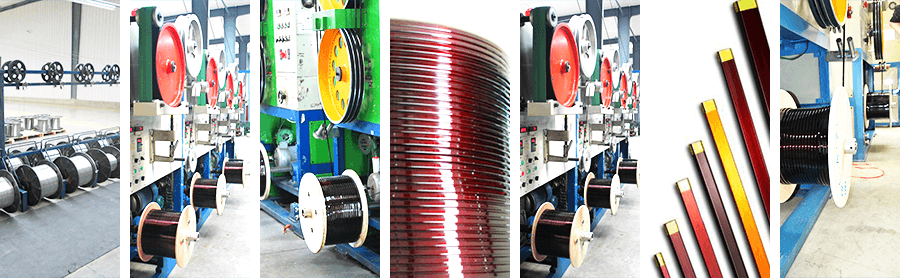

New Energy Vehicle Enamelled Flat Copper Wire

Production Characteristics

1.The maximum width-to-narrow ratio of the conductor is 30:1, and the insulation flexibility can achieve 2a, 2b bending without cracking.

2.Polyimide-Fluorine 46 composite film peel adhesion ≥1 lb.

3. Single-layer film sintering cutting stretch 15%, insulating film away from the conductor length ≤ 0.5b/d; double film/multi-layer sintering cutting stretch 10%, insulating film away from the conductor length ≤ 1b/d.

4. Our Enameled Flat(Rectangular) Copper Wire’s insulation layer and its copper paste firmly. It has good environment resistant and good stability.

Insulation: ELANTAS

Intelligent on-line monitoring equipment

| Item | Requirement of the standards |

| Stardards |

IEC, NEMA, GB, JIS |

| Electrical resistivity |

0.017241/0.02785Ω mm²/m |

| Breakdown voltage | After bending 2a and 2b, breakdown voltage ≥ 7500v (double layer/multilayer); breakdown voltage ≥ 5000v (single layer |

| Heat shock | The minimum Heat shock temperature 200/220/240℃ |

| Resistance to solvents | Standard solvent.Use a pencil of hardness”2H”the coating shall not be removed |

| Cut Through | 320,360,400℃, 2mins not break down |

Please fill in your procurement needs and contact information