- HOME

- PRODUCTS

- ABOUT US

- Panorama

- Download

- NEWS

- CONTACT

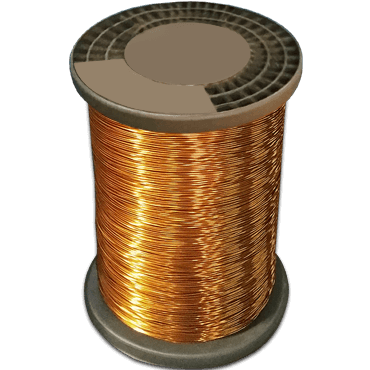

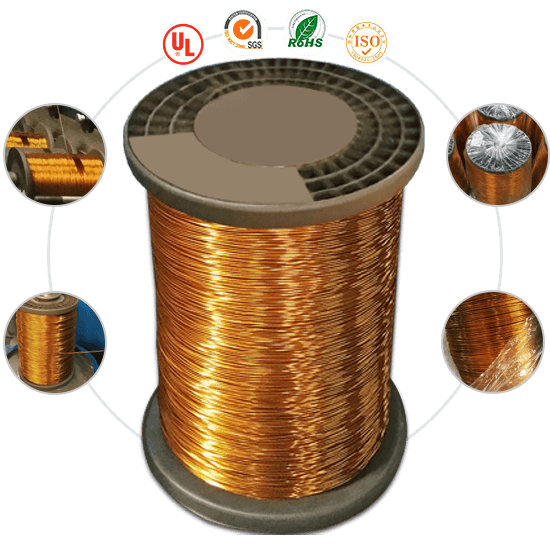

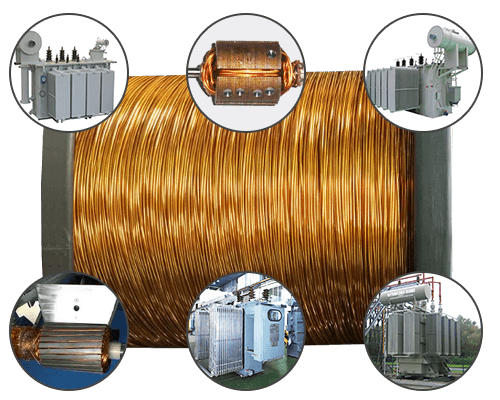

Polyvinyl Acetal/Formal Wire

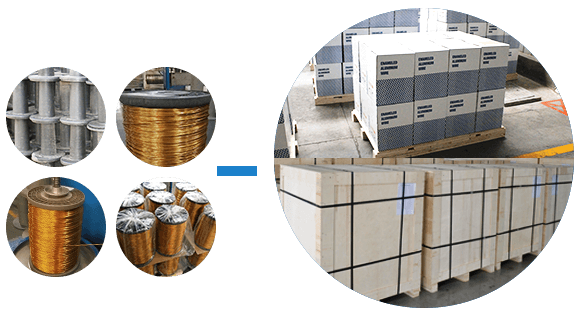

Size: Round:0.4-2.5mm,

Flat:15-40mm2

Thermal Class:105,120

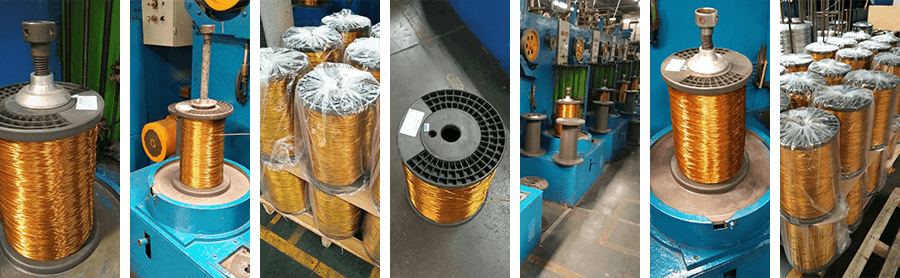

Production Characteristics

1. PVF is a film insulation composed of Polyvinyl Acetal and Phenolic.PVF was one of the first magnet wire insulations based on synthetic materials.Polyvinyl Formal - superior resistance to transformer oils. Polyvinyl Formal is a chief ingredient in PVA based wire enamels.

2. Our Polyvinal Acetal/Formal Wire has excellent resistance to transformer oil and provide outstanding toughness, flexibility and abrasion resistance.

3. Our Polyvinal Acetal/Formal Wire is highly versatile and good resistance to chemicals and excellent mechanical, thermal and electrical properties.

4.Our Polyvinal Acetal/ Formal is compatible with transformer oils. And It can retains insulating properties when exposed to cryogenic temperatures.

Insulation: ELANTAS

Intelligent on-line monitoring equipment

| Item | Requirement of the standards |

| Stardards | MW36-A GB/T6109/IEC60317-0-1 GB/T23312IEC60317-0-3 MW35-A |

| Electrical resistivity | 0.017241/0.02785 Ω mm²/m |

| Breakdown voltage | 2500/5000v |

| Heat shock | The minimum Heat shock temperature 200,220,240℃ |

| Resistance to solvents | Standard solvent.Use a pencil of hardness”2H”the coating shall not be removed |

| Cut Through | 320,360,400℃, 2mins not break down |

Please fill in your procurement needs and contact information