- HOME

- PRODUCTS

- ABOUT US

- Panorama

- Download

- NEWS

- CONTACT

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

We're here to help:Easy ways to get the answers you need.

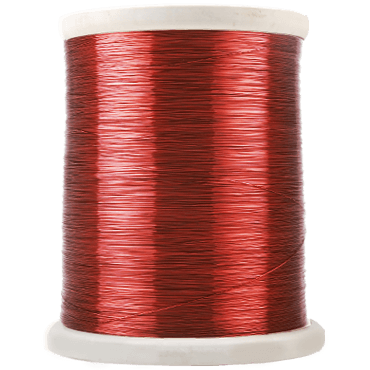

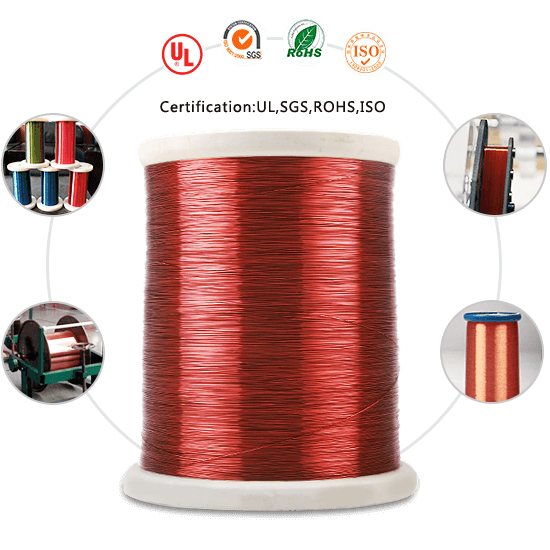

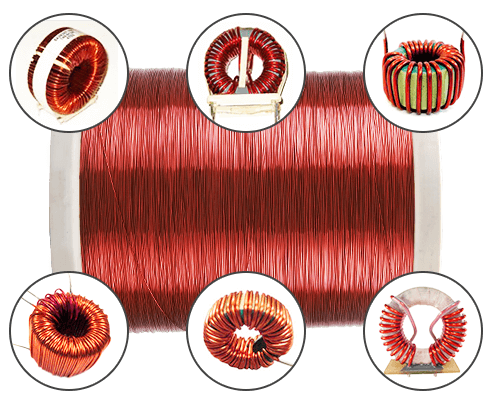

Enameled Round Copper Wire

Size: 0.025-4.5mm

Thermal Class:130,155,180,200,220

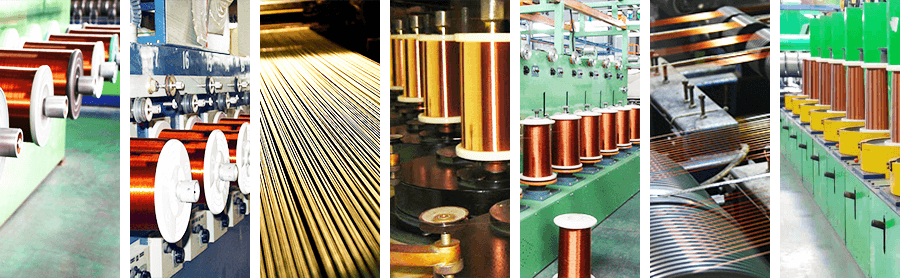

Production Characteristics

1.Enameled Copper Wire is one kind of magnet wire which is consisted of bare round copper which accord with EN 13601Cu-ETP standard as the conductor and multilayer insulation layers. The multilayer insulation layers can be polyester, modified polyester or polyesterimide and so on.

2.Our Enameled Round Copper Wire is one kind of enameled wire which has high heat resistance. Its temperature class can be from 130℃ to 220℃.

3. Our Enameled Round Copper Wire has excellent thermodynamic property, good mechanical abrasion resistance and good chemical resistance.

4. Our Enameled Round Copper Wire uses TU2 oxygen-free copper as raw material.TU2 oxygen-free copper has good conductivity and heat conductivity.

Insulation: ELANTAS

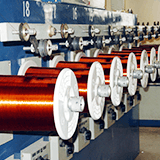

Intelligent on-line monitoring equipment

| Item | Requirement of the standards |

| Stardards | MW36-A GB/T6109/IEC60317-0-1 GB/T23312IEC60317-0-3 MW35-A |

| Electrical resistivity | 0.017241/0.02785 Ω mm²/m |

| Breakdown voltage | 2500/5000v |

| Heat shock | The minimum Heat shock temperature 200,220,240℃ |

| Resistance to solvents | Standard solvent.Use a pencil of hardness”2H”the coating shall not be removed |

| Cut Through | 320,360,400℃, 2mins not break down |

Please fill in your procurement needs and contact information